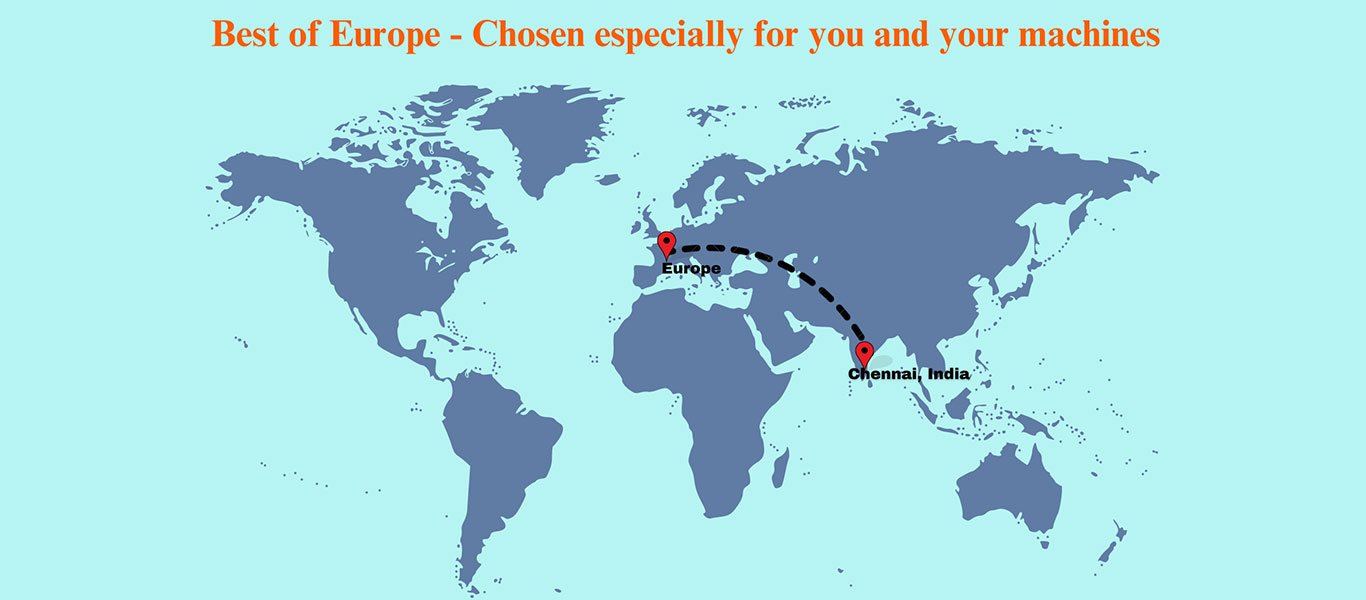

TRADELINK TRANSMISSION SERVICES PVT. LTD is a company that was incorporated after 31 years of operation as TRADELINK SERVICES to the Indian industry. The founder, Mr. Michael X. Gomez, gained extensive experience in the field of Mechanical Power Transmission during his time with Fenner India. He realized the lack of highly effective transmission products that were common in European and American industries but unheard of in Indian plants and equipment.

With this knowledge and experience, TRADELINK TRANSMISSION SERVICES PVT. LTD offers a range of time-tested and proven products that have been used in industrial applications all over the World. The company prides itself on recommending the right product for the right application, helping customers boost their output, enhance productivity reducing maintenance costs.