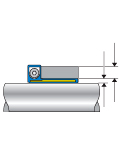

TRADELINK SERVICES now offers RULAND Rigid shaft couplings in one and two-piece designs, with and without keyways, in aluminum, carbon steel, and stainless steel. A large number of standard sizes are available in straight and step bore combinations to fit shafts ranging from 1/8" to 2" in the inch series and from 3mm to 50mm in the metric series. (see below)

The one-piece rigid coupling wraps around the shaft, providing high torsional holding power without damage to the shaft or fretting. The two-piece rigid coupling has the additional benefit of easy fitment, without disturbing other components – apart from easy dynamic balancing.